"...we wouldn’t even consider analysing this way in a traditional mesh-based system – it would take too long to get any useful information out. We would have ended up splitting the assembly into multiple simplified parts and running separate simulations for each. This would easily consume a day, or would only allow us to check a small subset of the components in the assembly, and likely be less accurate."

Tony Jones

Engineering Manager, Andron Handling Limited

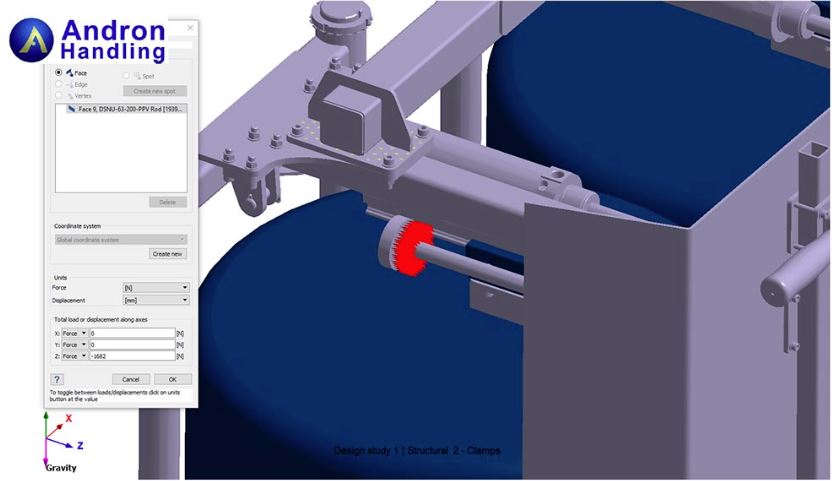

Figure 1 – Clamping force applied to piston rod

Figure 1 – Clamping force applied to piston rod

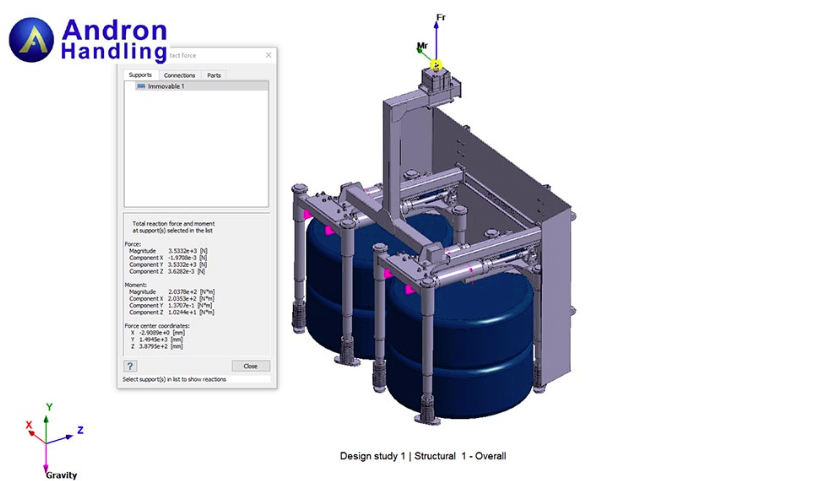

Reaction forces at the lifting eye are found to be within 1.5% of theoretical weight calculated in SOLIDWORKS. The figure in SimSolid is likely to be more accurate than SOLIDWORKS as measured weights have been applied to purchased items, e.g. linear bearings and cylinders.

Figure 2 – Reaction at lifting eye

Figure 2 – Reaction at lifting eye

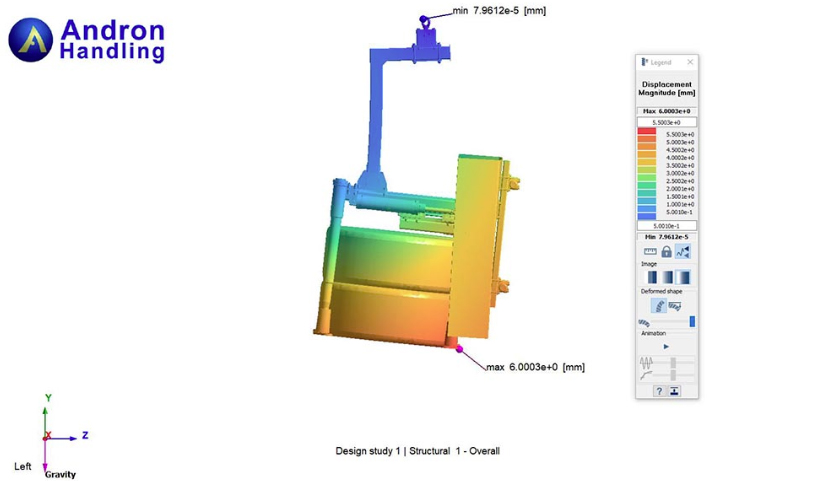

Figure 3 – Predicted displacement full system

Figure 3 – Predicted displacement full system

Figure 3 shows the predicted displacements due to gravity. The full assembly had 530 parts, with a simulation time of less than 50 seconds. This speed allowed Andron to run multiple design iterations in the budgeted time.

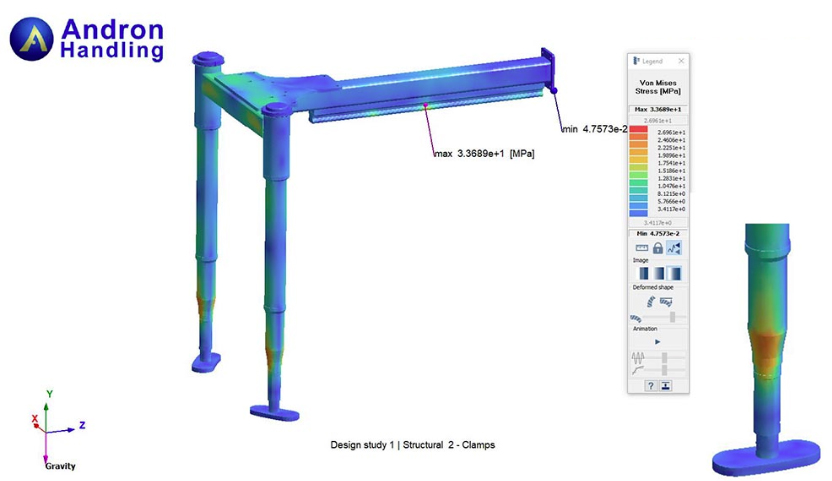

Figure 4 – Von Mises stress in clamping arms

Figure 4 – Von Mises stress in clamping arms

Figure 4 shows a detail view of the stress results in the clamping arms. Stress values were found to be well within limits, giving a predicted safety factor in the clamping arms of 8.7 against yield.

In conclusion, using SimSolid, Andron was able to quickly model the entire assembly in a very realistic manner with sliding connections, a clamping force on the pistons and matching reactions on the cylinder bodies. Total time from start to finish of the analysis (including all setup/preparation and fixing some errors in the CAD model) was only 1.5 hours.

"A final thought, we wouldn’t even consider analysing this way in a traditional mesh-based system – it would take too long to get any useful information out. We would have ended up splitting the assembly into multiple simplified parts and running separate simulations for each. This would easily consume a day, or would only allow us to check a small subset of the components in the assembly, and likely be less accurate." says Tony Jones, Engineering Manager at Andron Handling Limited.